Products

Categories

New Products

Brand:

LMSitem no.:

Full Automatic TelesPayment:

T/Tproduct origin:

Guangdong, ChinaColor:

Customizedshipping port:

Huangpu, GuangzhouLead Time:

90 Days

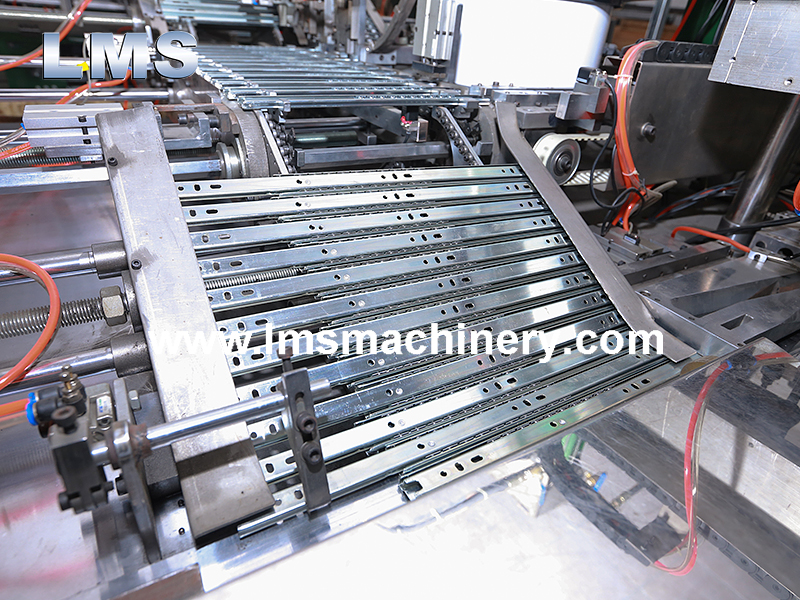

The production line is available for one-step completion of inner slide riveting, middle and outer slide assembling, and outer slide end bending, with high efficiency, high accuracy, well stability and long service life.

1. Material: CR / SS Drawer Slides

2. Profile Size: 45#/38#; Customization Available

3. Profile Length: 10’’ - 24’’

4. Productivity: 1000 - 1300 PCS / Hour

5. Plant Area Required: 60 M2 (10*6 M, Minimum)

6. Labor Required: 5 (Min.) - 8 (Max.) Workers (Including 1-2 Packers)

Inner Slide Riveting (Plastic Lock) — Middle Slide Assembly (Ball Cage & Balls & Plastic Stopper) — Outer Slide Assembling (Plastic Strip) — Auto Conveying — (QC Manual Adjusting) — Outer Slide End Bending (End Rubber) — Final Assembled Drawer Slides — PLC Control — (Packing).

Automatically assembly drawer slides for different lengths; high efficiency and save labor; widely applied in hardware industries.

1. Inner Slide Riveting Device, 1 Unit

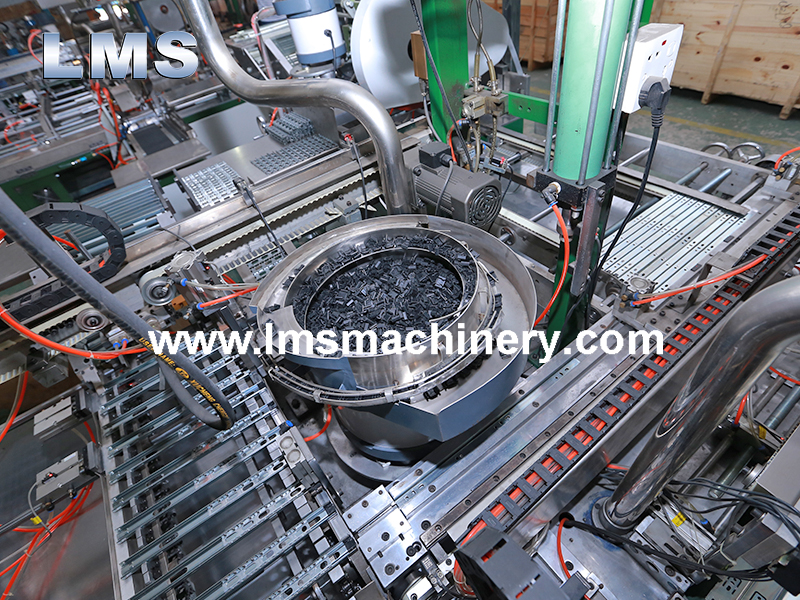

2. Auto Ball Assembly Device, 1 Unit

3. Mechanical Feeding Unit For Plastic Strips, 1 Unit

4. Outer Slide Assembly Device, 1 Unit

5. Conveying Belt, 1 Unit

6. End Bending Device, 1 Unit

7. Servo Motors, 7 Sets

8. Electrical Control System, 1 Unit

LMS Telescopic Channel Ball Bearing Drawer Slides Roll Forming Production Line

Light Gauge Steel Framing Machine

CATALOGUE:

Please send us roll forming profile with specifications, thickness and other processing requirements for our customized machine.If you need standard machine, please send us the model you want.

Copyright © LMS INTERNATIONAL LIMTED All Rights Reserved. 蜀ICP备17022790号,

川公网安备51010602002262

川公网安备51010602002262

the professional team to service !

86-28-87685256

[email protected]

[email protected] allyrafter

allyrafter 0086 13822 280343

0086 13822 280343