Products

Categories

New Products

Brand:

LMSitem no.:

CU DrywallPayment:

T/Tproduct origin:

Guangzhou, ChinaColor:

Customizedshipping port:

Huangpu, GuangzhouLead Time:

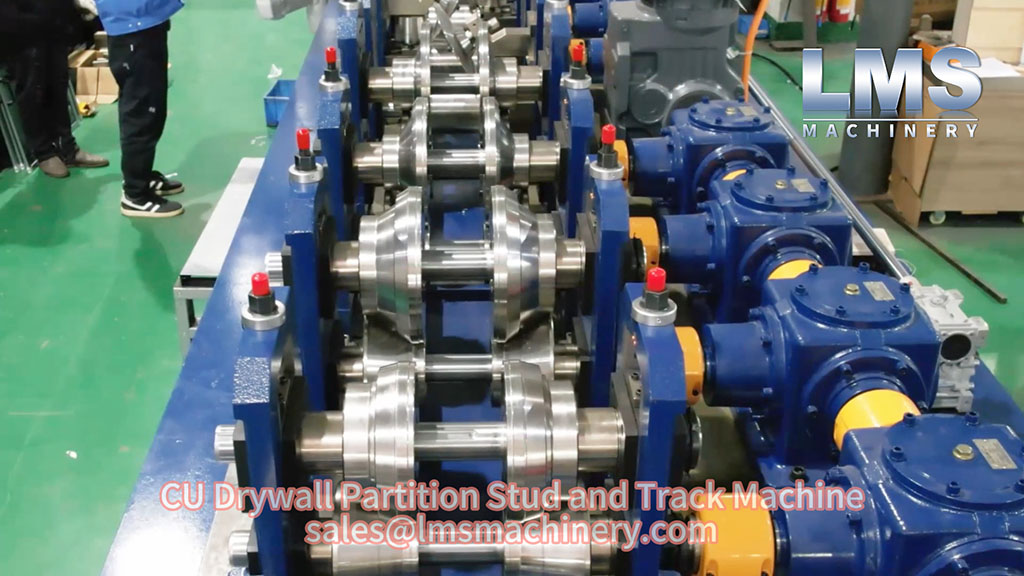

90 DaysLMS CU Drywall Partition Stud And Track Production Line is mainly used for the production of drywall partition stud and track. The full production line includes manual decoiler, roll forming machine, flying cut-off device, run-out table and control system. The maximum production speed from decoiling to discharging could be about 100 meters per minute.

The CU Channel Roll Forming Machine is engineered for precision and efficiency in light steel framing, drywall systems, and metal stud construction. Compatible with various steel specifications, it’s ideal for steel frame houses, prefabricated structures, and metal framing systems. Customizable to meet international standards and certifications, it’s the smart choice for modern industrialized building.

Material Coil - Decoiling - Roll Forming (- Flying Punching) - Flying Cutting Off - Finished Profile.

| Profile Shape | C/U Shape |

| Profile Size | C41 - 152.4mm (as per drawing) |

| Material Thickness | 0.38-0.9mm |

| Standard Machine Speed | Punching: 70-80 meters/min Non-punching: 100 meters/min |

| Power Supplier | 380V, 50Hz, 3Phrases(Customized) |

| Number of Forming Groups | 12 groups (excluding straightening) |

| Main Machine Power | 18.5 kw |

| Specification Change Motor | 1.8kw |

| Flying Punch and Flying Cut Motor | 5.5/4.1kw |

| Hydraulic Station Power | 11kw (Siemens) (Hydraulic components: Rexroth, German) |

| Hydraulic Cooling | wind coolant system |

| Wireless Remote Control for Main Machine | Standard |

| Punching and Cutting Molds | 2 sets of punching molds, 7 sets of cutting molds |

| Machine Size | 9500 x 1600 x 1600mm |

| Safety | Machine protection cover |

| Decoiler | 2000 kgs, hydraulic automatic tightening (1.1kw) |

| Automatic Packing Machine | Available |

Please send us roll forming profile with specifications, thickness and other processing requirements for our customized machine.If you need standard machine, please send us the model you want.

Copyright © LMS INTERNATIONAL LIMTED All Rights Reserved. 蜀ICP备17022790号,

川公网安备51010602002262

川公网安备51010602002262

the professional team to service !

86-28-87685256

[email protected]

[email protected] allyrafter

allyrafter 0086 13822 280343

0086 13822 280343