Categories

latest blog

Tags

FrameMac ® Light steel Frame House System Introduction

The light steel frame structure is supported by light steel ribbed beams and columns, working together. The physical properties are excellent and the construction period is short.

The heat preservation effect is good, and it is a new type of green energy-saving and environmentally-friendly building structure system. It is widely used in building structures of 3 floors and below. And combined structure with heavy steel structure, and 5 floors and below.

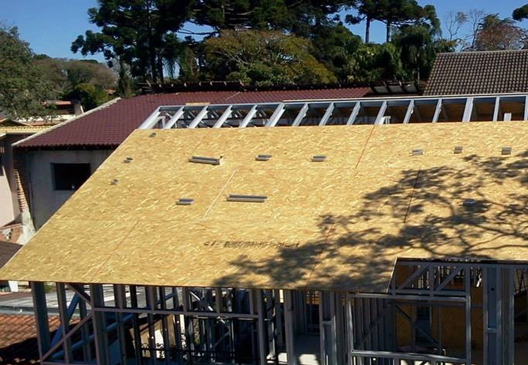

The light steel frame house consists of truss, OSB structural panels, waterproofing, and light duty roofing tiles (metal or asphalt shingles). The roof of the LGS structure can have various combinations of appearances. There are also a variety of materials.

Under the premise of ensuring waterproof technology, there are many options for appearance.

The floor of the light steel villa consists of a cold-formed light steel frame or composite beam, a floor OSB structural board, supporting items and connecting parts.

The materials used were oriented strand board, cement board, and plywood.

These light-weight floors can withstand loads of 316 to 365 kilograms per square meter.

The walls of light steel frame villas are mainly composed of wall frame columns, wall top beams, wall bottom beams, wall supports, wall panels and connectors.

Light steel villas generally use the inner cross wall as the structural load-bearing wall, and the wall column is a C-shaped light steel component.

The wall thickness depends on the load to be applied, usually 0.84 to 1.2 mm.

The spacing between wall columns is generally 400-600 mm, which can effectively withstand and reliably transmit vertical loads, and is easy to arrange.

The wall is filled with fiberglass wool, thermal insulation mortar, inorganic fibers.

The walls can be covered with fireproof gypsum board, wooden sauna board, bamboo fiberboard or metal carved board.

Insulation materials used in the exterior and roof of buildings can be used for a long time and can be insulated.

The glass wool is filled between the inner and outer walls and the floor joists, which effectively blocks the airborne audio part.

Impact sound of solid propagation:

The dividing wall uses two wall columns to form two walls with intermediate gaps;

An elastic construction with small slots is used to effectively reduce solid sound propagation between floors.

Previous:

Steel Frame House MachineNext:

FrameMac Light Steel Frame House MachineCopyright © LMS INTERNATIONAL LIMTED All Rights Reserved. 蜀ICP备17022790号,

川公网安备51010602002262

川公网安备51010602002262

the professional team to service !

86-28-87685256

[email protected]

[email protected] allyrafter

allyrafter 0086 13822 280343

0086 13822 280343