Products

Categories

New Products

Brand:

LMSitem no.:

Press BrakePayment:

T/Tproduct origin:

Guangdong, ChinaColor:

Customizedshipping port:

Huangpu, ChinaLead Time:

90 Days

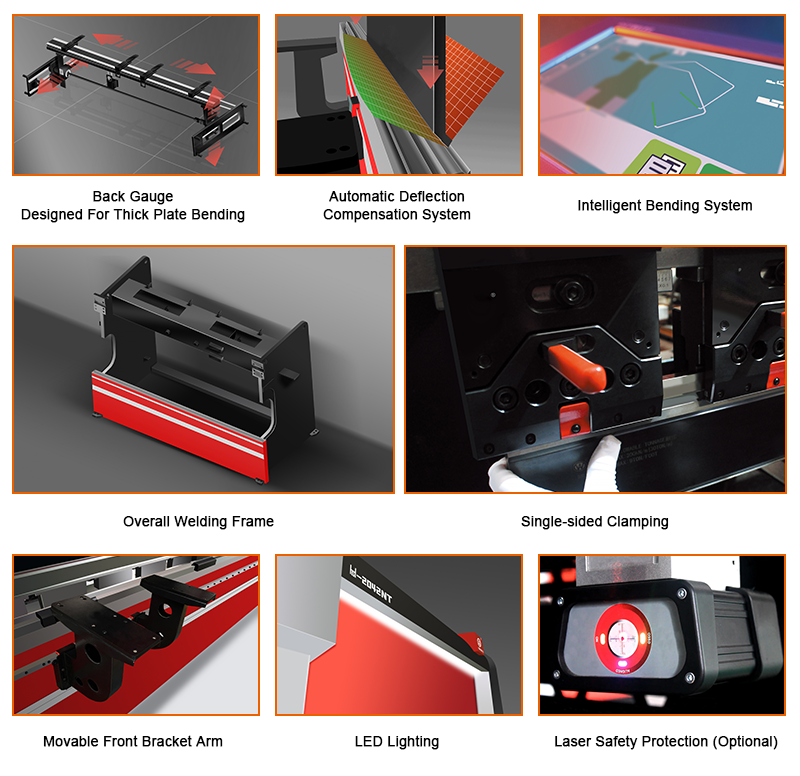

Downstroke CNC Hydraulic Bending Machine is specifically developed for thick and large plates bending, with overall welding frame and intelligent bending system, greatly improves the processing accuracy and efficiency. And the rich and practical auxiliary functions help to simplify the production process and give play to the strong performance of the machine to better.

| Model | GH-8060NT | GH-5060NT | GH-4060NT | GH-3260NT | GH-3242NT | GH-3232NT | |

| Nominal Pressure | 8000 KN | 5000 KN | 4000 KN | 3200 KN | 3200 KN | 3200 KN | |

| Slider Stroke | 400 mm | 300 mm | 300 mm | 300 mm | 300 mm | 300 mm | |

| Numerical Control Axis Number | Y1 / Y2 / X / R / V | Y1 / Y2 / X / R / V | Y1 / Y2 / X / R / V | Y1 / Y2 / X / R / V 4+1 | Y1 / Y2 / X / R / V | Y1 / Y2 / X / R / V | |

| Main Motor Power | 55 KW | 37 KW | 30 KW | 14.5 KW | 14.5 KW | 14.5 KW | |

| Workbench Length | 6000 mm | 6000 mm | 6000 mm | 6000 mm | 4200 mm | 3200 mm | |

| Open Height | 800 mm | 600 mm | 500 mm | 500 mm | 500 mm | 500 mm | |

| Running Speed of Slider | Fast | 80 mm/s | 100 mm/s | 100 mm/s | 115 mm/s | 115 mm/s | 115 mm/s |

| Work | 8 mm/s | 8 mm/s | 8 mm/s | 8 mm/s | 9.5 mm/s | 9.5 mm/s | |

| Return Travel | 60 mm/s | 65 mm/s | 90 mm/s | 125 mm/s | 125 mm/s | 125 mm/s | |

| Back Gauge R Axis | Travel | 150 mm | 150 mm | 150 mm | 150 mm | 150 mm | 150 mm |

| Max. Running Speed | 150 mm/s | 150 mm/s | 150 mm/s | 150 mm/s | 150 mm/s | 150 mm/s | |

| Repeat Positioning Accuracy | ≤ 0.05 mm | ≤ 0.05 mm | ≤ 0.05 mm | ≤ 0.05 mm | ≤ 0.05 mm | ≤ 0.05 mm | |

| Back Gauge X Axis | Travel | 600 mm | 600 mm | 600 mm | 600 mm | 600 mm | 600 mm |

| Max. Running Speed | 300 mm/s | 300 mm/s | 300 mm/s | 250 mm/s | 250 mm/s | 250 mm/s | |

| Repeat Positioning Accuracy | ≤ 0.05 mm | ≤ 0.05 mm | ≤ 0.05 mm | ≤ 0.05 mm | ≤ 0.05 mm | ≤ 0.05 mm | |

| External Length of Machine | 6600 mm | 6600 mm | 6600 mm | 6300 mm | 4600 mm | 3450 mm | |

| External Width of Machine | 3400 mm | 2200 mm | 2200 mm | 2350 mm | 2200 mm | 2200 mm | |

| Total Height of Machine | 5300 mm | 3500 mm | 3500 mm | 3200 mm | 3200 mm | 3100 mm | |

| Column Distance | 4800 mm | 4800 mm | 4800 mm | 5180 mm | 3400 mm | 2700 mm | |

| Throat Depth | 700 mm | 450 mm | 450 mm | 450 mm | 450 mm | 450 mm | |

| Machine Weight | ≥ 79000 KGS | ≥ 45000 KGS | ≥ 38000 KGS | ≥ 29000 KGS | ≥ 20500 KGS | ≥ 17500 KGS | |

| Notes: Y1, Y2 Axis: control the up and down movement of slider. X Axis: control the forward and backward movement of back gauge. R Axis: control the up and down movement of back gauge. V Axis: mechanical deflection compensation. |

|||||||

| Model | GH-2542NT | GH-2042NT | GH-1642NT | GH-1632NT | GH-1032NT | GH-8025NT | GH-5020NT | |

| Nominal Pressure | 2500 KN | 2000 KN | 1600 KN | 1600 KN | 1000 KN | 800 KN | 500 KN | |

| Slider Stroke | 250 mm | 200 mm | 200 mm | 200 mm | 200 mm | 200 mm | 180 mm | |

| Numerical Control Axis Number | Y1 / Y2 / X / R / V | Y1 / Y2 / X / R / V | Y1 / Y2 / X / R / V | Y1 / Y2 / X / R / V | Y1 / Y2 / X / R / V | Y1 / Y2 / X / R / V | Y1 / Y2 / X / R | |

| Main Motor Power | 14.5 KW | 14.5 KW | 11 KW | 11 KW | 7.5 KW | 7.5 KW | 7.5 KW | |

| Workbench Length | 4200 mm | 4200 mm | 4200 mm | 3200 mm | 3200 mm | 2500 mm | 2000 mm | |

| Open Height | 460 mm | 460 mm | 460 mm | 460 mm | 460 mm | 460 mm | 440 mm | |

| Running Speed of Slider | Fast | 130 mm/s | 130 mm/s | 150 mm/s | 150 mm/s | 150 mm/s | 150 mm/s | 150 mm/s |

| Work | 9 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | 10 mm/s | |

| Return Travel | 115 mm/s | 105 mm/s | 130 mm/s | 130 mm/s | 130 mm/s | 130 mm/s | 130 mm/s | |

| Back Gauge R Axis | Travel | 150 mm | 150 mm | 150 mm | 150 mm | 150 mm | 150 mm | 150 mm |

| Max. Running Speed | 150 mm/s | 150 mm/s | 150 mm/s | 150 mm/s | 150 mm/s | 150 mm/s | 150 mm/s | |

| Repeat Positioning Accuracy | ≤ 0.05 mm | ≤ 0.05 mm | ≤ 0.05 mm | ≤ 0.05 mm | ≤ 0.05 mm | ≤ 0.05 mm | ≤ 0.05 mm | |

| Back Gauge X Axis | Travel | 600 mm | 600 mm | 600 mm | 600 mm | 600 mm | 600 mm | 600 mm |

| Max. Running Speed | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 350 mm/s | 350 mm/s | 350 mm/s | |

| Repeat Positioning Accuracy | ≤ 0.05 mm | ≤ 0.05 mm | ≤ 0.05 mm | ≤ 0.05 mm | ≤ 0.05 mm | ≤ 0.05 mm | ≤ 0.05 mm | |

| External Length of Machine | 4600 mm | 4450 mm | 4550 mm | 3450 mm | 3500 mm | 2800 mm | 2300 mm | |

| External Width of Machine | 2100 mm | 1800 mm | 1780 mm | 1800 mm | 1600 mm | 1500 mm | 1660 mm | |

| Total Height of Machine | 2900 mm | 2800 mm | 2800 mm | 2800 mm | 2750 mm | 2600 mm | 2500 mm | |

| Column Distance | 3400 mm | 3400 mm | 3400 mm | 2750 mm | 2900 mm | 2000 mm | 1710 mm | |

| Throat Depth | 400 mm | 400 mm | 400 mm | 400 mm | 400 mm | 320 mm | 300 mm | |

| Machine Weight | ≥ 15500 KGS | ≥ 14000 KGS | ≥ 12000 KGS | ≥ 9200 KGS | ≥ 8000 KGS | ≥ 5500 KGS | ≥ 4300 KGS | |

| Notes: Y1, Y2 Axis: control the up and down movement of slider. X Axis: control the forward and backward movement of back gauge. R Axis: control the up and down movement of back gauge. V Axis: mechanical deflection compensation. |

||||||||

LMS TDC Flange Roll Forming Machine

HVAC Steel Smoke Fire Damper Automatic Production Line

Upstroke Press Brake Bending Machine With NC Control

Duct Manufacturing Auto Line I

Duct Manufacturing Auto Line VI

Duct Manufacturing Auto Line II

Duct Manufacturing Auto Line III

Duct Manufacturing Auto Line IV

Duct Manufacturing Auto Line V

Duct Manufacturing Auto Line VII

LMS Fire Damper Outer Frame Full Automatic Production Line

LMS Fire Damper Blade Forming Machine

LMS Fire Damper Leaf Spring Forming Machine

LMS Fire Damper Support Bar Forming Machine

LMS Fire Damper Positive Pressure Air Supply Outlet Production Line

LMS Fire Damper Baffle Forming Machine

LMS Fire Damper Riveting Platform

Light Gauge Steel Framing Machine

Please send us roll forming profile with specifications, thickness and other processing requirements for our customized machine.If you need standard machine, please send us the model you want.

Copyright © LMS INTERNATIONAL LIMTED All Rights Reserved. 蜀ICP备17022790号,

川公网安备51010602002262

川公网安备51010602002262

the professional team to service !

86-28-87685256

[email protected]

[email protected] allyrafter

allyrafter 0086 13822 280343

0086 13822 280343