Products

Categories

New Products

Brand:

LMSitem no.:

Floor Decking MCPayment:

T/Tproduct origin:

ChinaColor:

Customizedshipping port:

HuangpuLead Time:

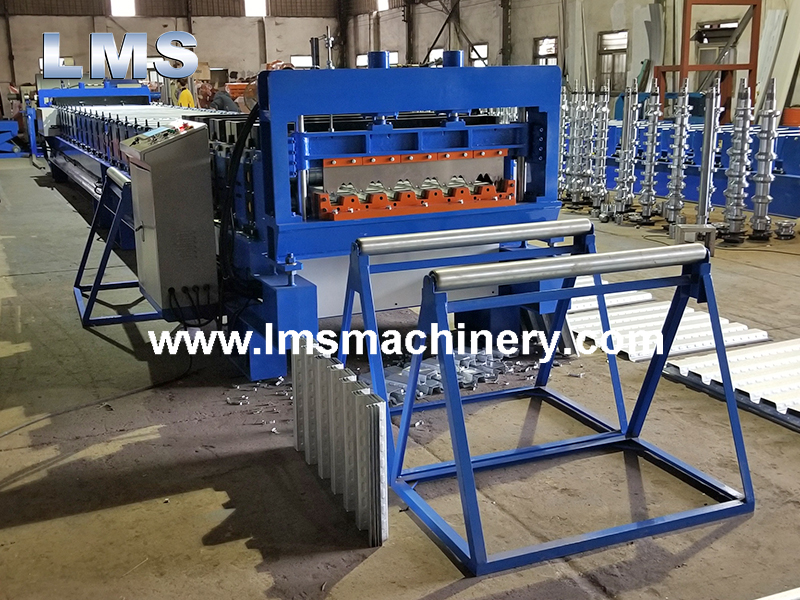

90 DaysLMS Floor Decking Roll Forming Machine is cost-effective with over 10 years work life. Rollers are designed by Germany COPRA software and surface is polished and hard chrome plated, transmitting smoothly with low noise, suitable for steel floor deck mass production. The production line is equipped with PLC & electrical accessories of famous brand, such as MITSUBISHI, SCHNEIDER, OMRON.

Suitable Raw-Material Specification:

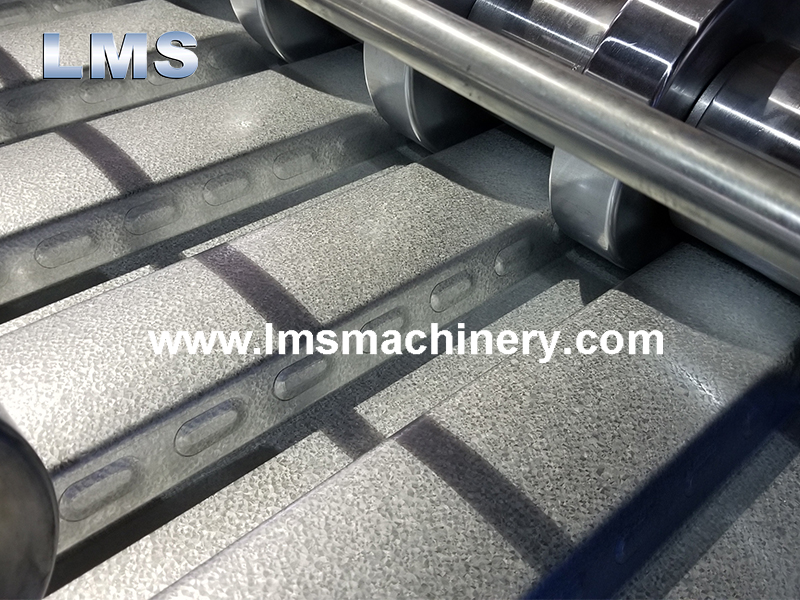

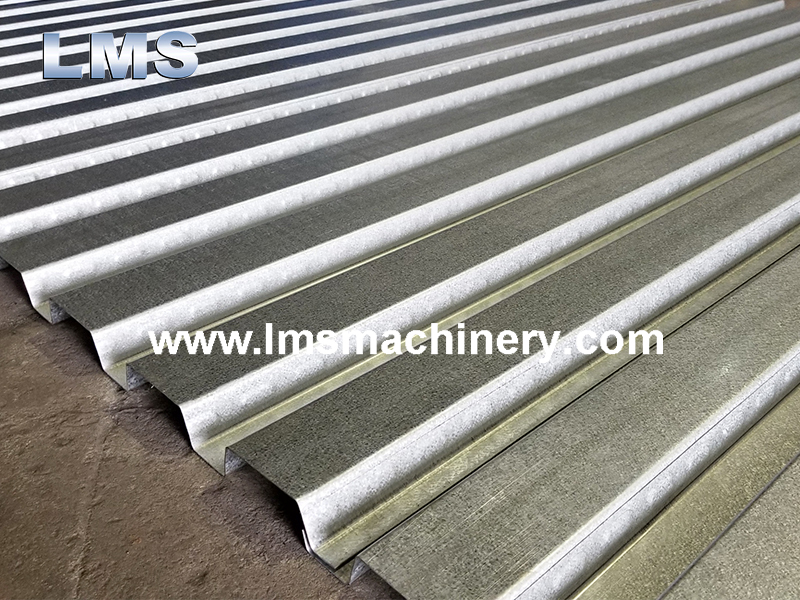

1. Suitable Material: Galvanize Steel

2. Material Thickness: Gauge 18 - 21 (0.8 - 1.2 MM)

3. Effective Width: 36” (914.4 MM)

4. Material Width: 49.21” (1250 MM)

5. Material Strength: G550 MPa

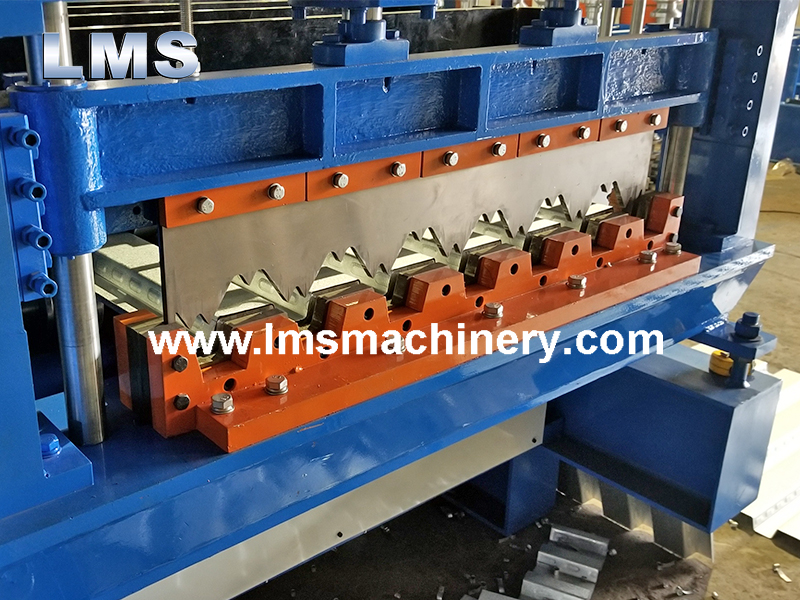

Material Coil → Hydraulic Decoiling → The Front Shear → Roll Forming → Hydraulic Cutting Off → Final Profile.

1. Auto Hydraulic Decoiler: 1 Unit

2. Coil Car: 1 Unit

3. Front Shearing Device: 1 Set

4. Roll Forming Device: 1 Unit

5. Hydraulic Cut-Off Device: 1 Set

6. Auto Run-Out Table: 3 Sets

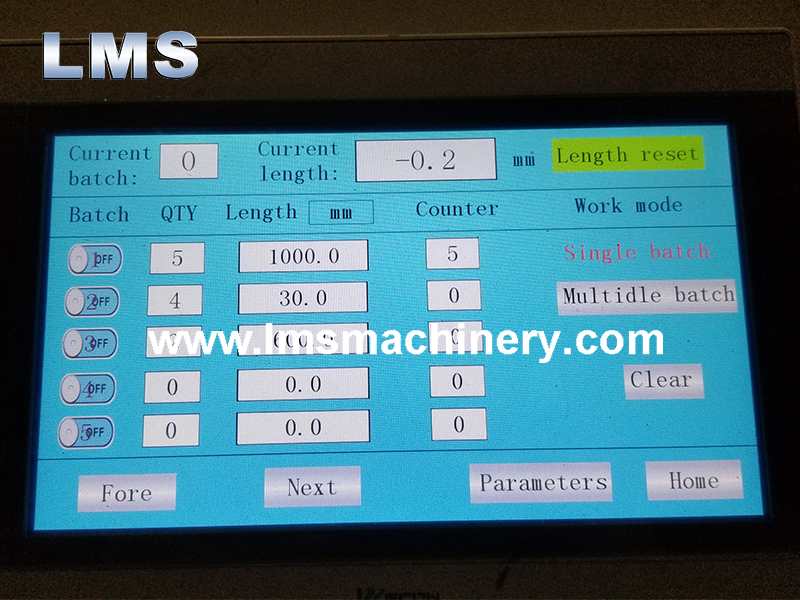

7. Electrical Control System: 1 Unit

LMS Metal Corrugated Roof Tile Roll Forming Machine

LMS Trapezoidal Pattern Roof Tile Roll Forming Machine

LMS Step Tile Roof Roll Forming Machine

LMS Steel Ridge Cap Roof Roll Forming Machine

LMS Roof Standing Seam Roll Forming Machine

LMS Metal Trapezoidal Roof Roll Forming Machine

LMS R-Panel Roof Tile Roll Forming Machine

LMS C / Z Purlin Roll Forming Machine

LMS Double Layer Roof Panel Roll Forming Machine

LMS CZ Fast-Changing Purlin Roll Forming Machine

Light Gauge Steel Framing Machine

Please send us roll forming profile with specifications, thickness and other processing requirements for our customized machine.If you need standard machine, please send us the model you want.

Copyright © LMS INTERNATIONAL LIMTED All Rights Reserved. 蜀ICP备17022790号,

川公网安备51010602002262

川公网安备51010602002262

the professional team to service !

86-28-87685256

[email protected]

[email protected] allyrafter

allyrafter 0086 13822 280343

0086 13822 280343