Products

Categories

New Products

Brand:

LMSitem no.:

Ceiling Tile MachinePayment:

T/Tproduct origin:

Guangdong, ChinaColor:

Customizedshipping port:

Huangpu, GuangzhouLead Time:

30 Days

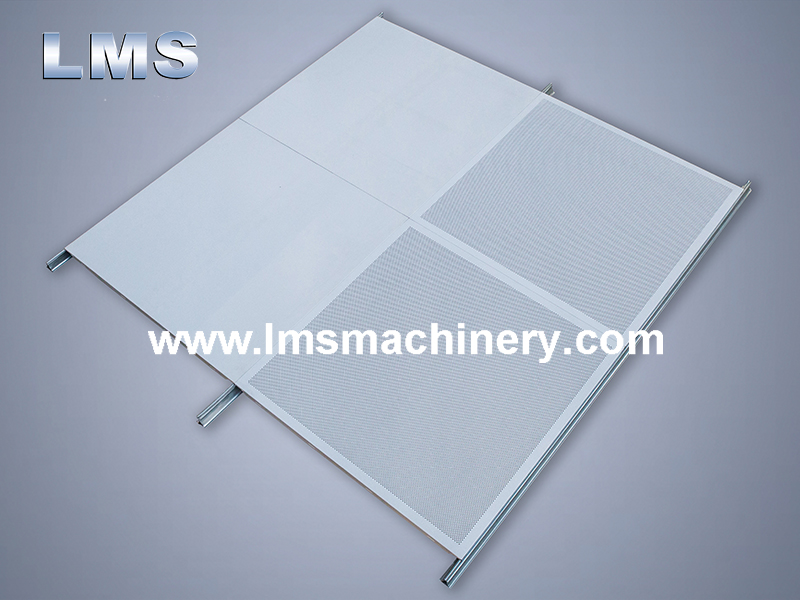

LMS Ceiling Tile 600×600 Full Auto Production Line With Film Applicator is mainly used for the production of decoration metal ceiling tiles. The full production line includes automatic material decoiler, first leveling, NC feeding perforation, corner cutting, second leveling, manipulator and bending. This production line is full automatic, with high precision and fast production speed. It is full automatic production line for 600×600 ceiling panels. Both clip-in and lay-in designs could be produced by changing tools on the same machine. Production speed from decoiling to discharging (including perforation) could be about 5 - 6 pieces per minute. Other revelant metal ceiling machines could be customized as well, welcome to send samples or drawings for customization.

1. Material: Aluminum Coil / Steel Coil

2. Material Thickness: 0.4 - 0.55 MM (Customized)

3. Punching Hole: Ø 1.8 MM (Customized)

4. Profile Size: 600 × 600 MM (As Per Drawing)

Decoiling - Simple Film Applicator - 1# Leveling - Perforation (Yangli Press) - Corner Cut - Conveyor - 2# Leveling - Turnover Unit - Manipulator - Bending - Finished Tile.

| NO. | Equipment | Specification | Qty. |

| 1 | Hydraulic Decoiler | With Coil Car (Optional) | 1 Unit |

| 2 | 1# Leveler | Including Integrated Film Applicator | 1 Unit |

| 3 | Perforation (Power Press) | With Servo Feeder | 1 Unit |

| 4 | Corner Cut (Hydraulic Press) | 40T (600×600) / 80T (1200×600) (Optional) | 1 Unit |

| 5 | Conveyors |

1# - Between Cutting Unit And 2# Leveler. 2# - After Bending |

2 Units In Total |

| 6 | 2# Leveler | 21 Leveling Rolls | 1 Unit |

| 7 | Turnover Unit | Integrated In Conveyor | 1 Unit |

| 8 | Manipulator | Transfer Material After Turnover Into Bending Tool | 1 Unit |

| 9 | Bending Press | 120T For 600×600 Forming (Clip-In / Lay-In) (Optional) | 1 Unit |

| 10 | Control System | YASKAWA Servo Motor; PANASONIC PLC | 1 Unit |

| 11 | Tools (Customized) | Perforation, Corner Cutting And Bending Tools | 1 Set |

LMS Drywall Partition Stud And Track Roll Forming Machine

Ceiling U Baffle Roll Forming Machine

Ceiling Triangle Grid Roll Forming Machine

Ceiling T Grid T Bar Roll Forming Auto Line

Ceiling Strip Roll Forming Machine

LMS Open Cell Ceiling Grilyato Production Line

Ceiling Furring Roll Forming Machine

Ceiling Carrier Roll Forming Machine

Light Gauge Steel Framing Machine

Please send us roll forming profile with specifications, thickness and other processing requirements for our customized machine.If you need standard machine, please send us the model you want.

Copyright © LMS INTERNATIONAL LIMTED All Rights Reserved. 蜀ICP备17022790号,

川公网安备51010602002262

川公网安备51010602002262

the professional team to service !

86-28-87685256

[email protected]

[email protected] allyrafter

allyrafter 0086 13822 280343

0086 13822 280343